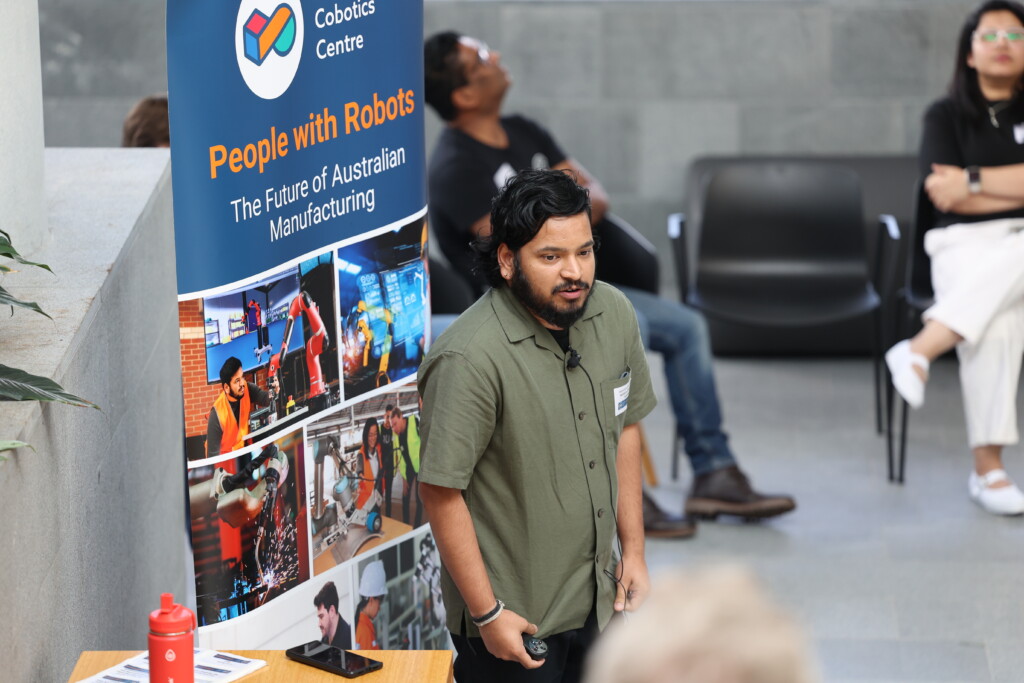

The Australian Cobotics Centre successfully hosted its first Industry Symposium and Mini-Expo on Thursday, 5th December 2024, at the QUT Kelvin Grove campus in Brisbane. This engaging event, sponsored by ARM Hub AI Adopt Centre and the Queensland Government’s Department of Natural Resources and Mines, Manufacturing and Regional and Rural Development, brought together over 100 manufacturers, researchers, and industry professionals to explore the latest advancements in advanced manufacturing technologies and discuss the evolving role of humans in the future of manufacturing.

Event Highlights

Keynote talk

Professor Cori Stewart, CEO of ARM Hub gave a keynote talk about the current state of Australian manufacturing and how AI can enhance productivity.

Industry talks

- Continuous Improvement in manufacturing, Kettina Materna, Cook Medical

-

SME Experiences of R&D in shower base manufacturing, Rebecca Lowery, Universal Shower Base and Dr Mariadas Roshan, Swinburne University of Technology

-

Lessons learned from the implementation of Collaborative Robotics in surgery, Dr Tom Williamson, Stryker

-

Tools to utilise data for decision making, Dr Roozbeh Derakhshan, ARM Hub AI Adopt Centre

-

Insights from international experiences with cobots in manufacturing, Prof Rainer Mueller, ZeMA

Panel Discussion: “The Future of Australian Manufacturing: From AI to Humanoids, Where Does the Human Fit?”

One of the standout moments of the event was the panel discussion facilitated by Professor Jonathan Roberts, Director of the Australian Cobotics Centre. Panelists included:

- Dr Cornelis van Niekerk, Weld Australia

- Associate Professor Penny Williams, QUT Centre for Decent Work and Industry and Australian Cobotics Centre

- Dr Sue Keay, Robotics Australia Group

- Richard (Ric) Pruss, Workr Labs

This lively discussion, facilitated by Centre Director, Professor Jonathan Roberts, explored the transformative impact of technologies like AI and humanoid robots on manufacturing. The panel also addressed the importance of maintaining a human-centered approach in an increasingly automated industry, sparking thought-provoking dialogue among attendees.

Mini-Expo

The mini-expo was a highlight for many participants, offering hands-on experiences with cobotic technologies. Live research demonstrations and stands from exhibitors including DCISIV Technolgogies, Queensland XR Hub, ARM Hub AI Adopt Centre, the Queensland Government’s Department of Natural Resources and Mines, Manufacturing and Regional and Rural Development showcased the potential of these innovations to enhance productivity, improve workplace safety, and support the competitiveness of Australian manufacturers.

Looking Ahead

Events like this symposium play a crucial role in strengthening industry connections and disseminating research outcomes.

For those who couldn’t attend, stay tuned for future events and opportunities to engage with the Centre’s groundbreaking work. Check out our program and project pages to learn more about our ongoing projects and upcoming initiatives.

We extend our gratitude to all speakers, panelists, and attendees who made the 2024 Industry Symposium a resounding success.