By James Dwyer and Dr Valeria Macalupu (both QUT)

A tangible, adaptable and modular interface for embodied explorations of human-robot interaction concepts.

As robots become increasingly integrated into various industries, from healthcare to manufacturing, the need for intuitive and adaptable tools to design and test robotic movements has never been greater. Traditional approaches often rely on expensive simulations or complex hardware setups, which can restrict early-stage experimentation and limit participation from non-expert stakeholders. The kinematic puppet offers a refreshing alternative by combining hands-on prototyping with virtual simulation, making it easier for anyone to explore and refine robot motion. This work is particularly critical for exploring intuitive ways surgeons can collaborate with robots in the operating room, improving Robot-Assisted Surgery (RAS).

What is the kinematic puppet?

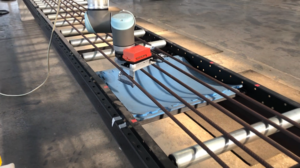

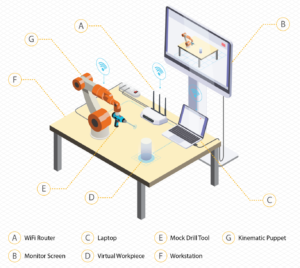

The kinematic puppet is an innovative tool that combines physical prototyping and virtual simulation to simplify the design and testing of robot movements and human-robot interactions. The physical component is a modular puppet constructed from 3D-printed joints equipped with rotary encoders and connected by PVC linkages. This flexible and cost-effective setup allows users to customise a robot arm to suit a variety of needs by adjusting linkage lengths and joint attachments.

On the digital side, a virtual simulation environment (developed in Unreal Engine) creates a real-time digital twin of the physical puppet. This integration via Wi-Fi/UDP enables immediate visualisation and testing of HRI concepts. By bridging the gap between physical manipulation and digital analysis, the kinematic puppet makes it easier for anyone to experiment with and refine robot motion in an interactive and accessible way.

How does the user interact with the puppet?

In the demonstration, users engage with the system by physically manipulating the kinematic puppet to control a digital twin of the robot arm, guiding it through a virtual cutting task. As they direct the arm’s movements, a virtual cutting tool simulates material removal in real time.

The system provides continuous feedback through both visual displays and haptic responses, creating an immersive and intuitive experience. This interactive environment challenges participants to balance precision and speed, highlighting the importance of both accuracy and efficiency in robotic tasks.

By making the abstract process of programming robotic movements tangible, the kinematic puppet empowers users to experiment and learn in a dynamic environment.

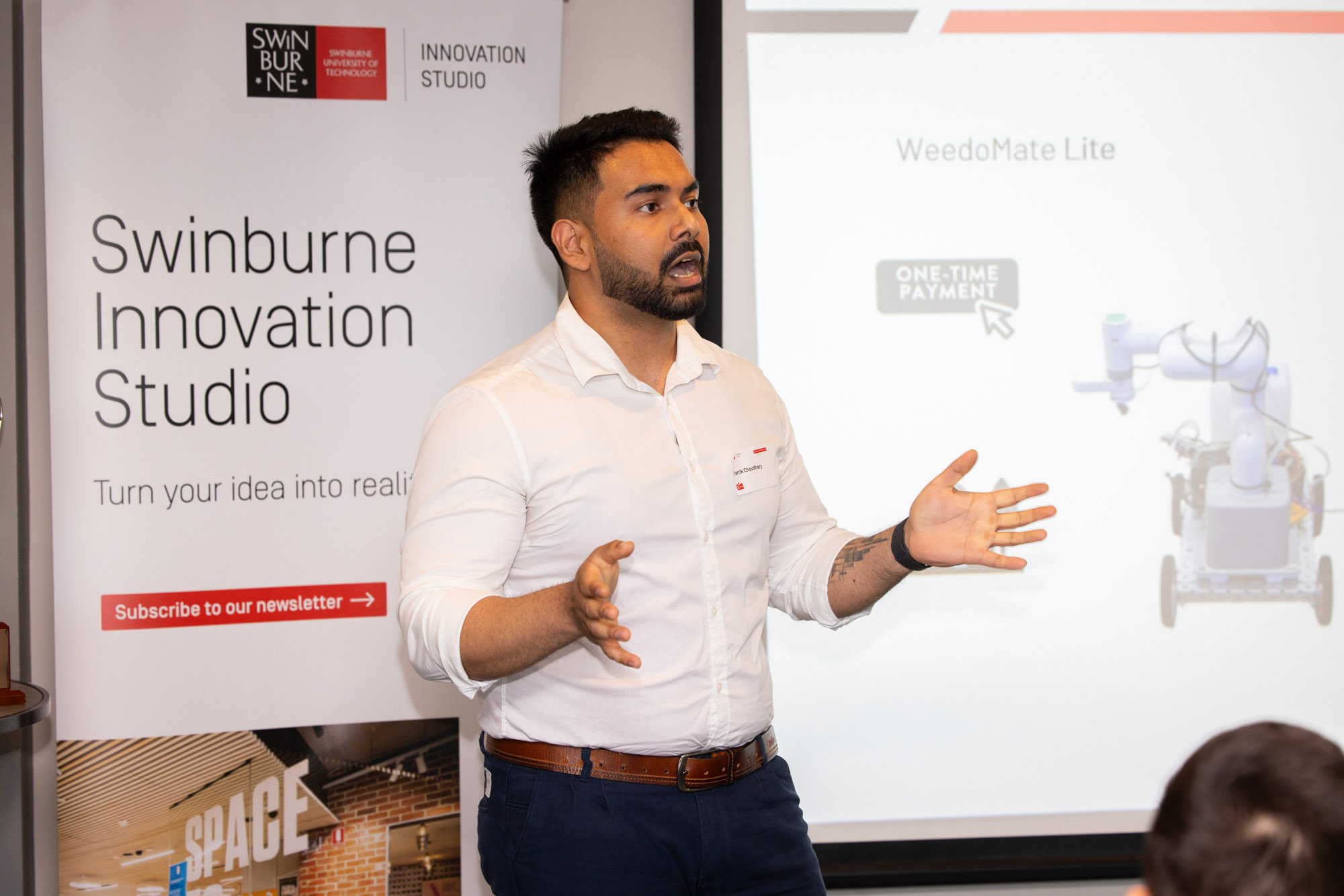

Demonstration at HRI 2025 – An experience for HDR students.

Presenting the Kinematic Puppet at the Human-Robot Interaction Conference 2025 provided valuable insights into how our research resonates with the broader robotics community. Attendees were particularly drawn to the system’s modularity and reconfigurability and appreciated the puppetry-based approach as an intuitive method for exploring human-robot interaction concepts.

The demonstration wasn’t without challenges. Technical issues before the demo required some mildly frantic rebuilding of the code solution the morning of, highlighting a common research reality: experimental prototypes often accumulate small bugs through iterative development that compound unexpectedly. An all-too-common challenge that reflects the messy nature of research and something that isn’t always visible in polished publications.

Reviewer feedback highlighted potential applications we hadn’t considered, particularly around improving accessibility of research technologies. While most attendees engaged enthusiastically with the concept, some appeared to struggle to connect it to their work. It took time for me to find effective ways to explain the purpose and value of the approach—a good reminder that not every method resonates equally in a diverse field and how important it is to tailor explanations to your audience, even within a given research community.

For an HDR student, this experience underscores the importance of exposing your work to the research community early. The value lies not in positive reception, but in the process of presenting the work itself. Getting to explain my work to others forced me to articulate and refine my thinking, an opportunity that is missed when work is conducted in isolation. These interactions helped me understand how my work fits within the broader landscape and sparked new reflections on its purpose and potential applications that I might have missed otherwise.

You can read more about this demo here: https://dl.acm.org/doi/10.5555/3721488.3721764

Dwyer, J. L., Johansen, S. S., Donovan, J., Rittenbruch, M., & Gomez, R. (2025). What Would Jim Henson Do? Roleplaying Human-Robot Collaborations Through Puppeteering Proceedings of the 2025 ACM/IEEE International Conference on Human-Robot Interaction, Melbourne, Australia.

TL; DR.

- Accessible Design: The kinematic puppet combines physical prototyping with virtual simulation for intuitive human-robot interaction design.

- Intuitive Feedback for Seamless Experience: Users control a customisable robot arm through hands-on manipulation while receiving real-time visual and haptic feedback. This novel approach supports Robot-Assisted Surgery design processes by enabling the intuitive exploration of human-robot interactions.

- Creative Inspiration: Inspired by film animation techniques and puppeteering, this low-cost, adaptable tool enables rapid prototyping and innovative experimentation in human-robot interaction research more broadly.

- Communicating Complex Research Concepts: Often requires tailoring explanations to diverse audiences. Even within a specialised community like HRI, individuals connect with ideas differently, and finding effective ways to articulate the purpose and value of novel methodological approaches is an ongoing challenge that improves with practice.

- Early Exposure of Research Work: Presenting research work to the community provides invaluable benefits beyond simply positive reception. The process of presenting forces the articulation and refinement of ideas, reveals how your work fits within the broader research landscape, and often uncovers applications and connections you might otherwise miss when working in isolation.