A cobot equipped with a laser-mounted end-effector points at a detected short bar. A green dot marks the identified short bar, providing a clear visual cue for operators.

A demonstration of vision-guided collaborative robotics has shown what the future of automation in steel product manufacturing could look like. As part of the Australian Cobotics Centre’s (ACC) Biomimic Cobots Program, this research initiative fosters university-industry partnerships to drive technological advancements. Researchers from the Robotics Institute at UTS and the Research Engineering Facility at QUT, in collaboration with InfraBuild, deployed a custom AI-based “shorts” detection system integrated with a collaborative robot (cobot) that aims to enhance safety and maintain quality control in an active production environment.

The industry partner, InfraBuild, operates a manufacturing process that involves producing hot steel bars in various shapes and sizes. Quality control is maintained through a manual process where workers, operating in 12-hour rotating shifts, identify and remove defective short-length bars, known as “shorts”, from a conveyor. This task is both physically demanding and requires continuous focus to reduce errors and ensure workplace safety.

A key requirement for the solution was that it integrate seamlessly into existing operations without necessitating extensive modifications to plant, equipment, or processes. However, due to the wide variety of products that InfraBuild manufactures, off-the-shelf automation solutions were not suitable for accurately identifying and removing every type of bar produced. Given these requirements, a vision system consisting of various sensing modalities and a cobot were selected. This choice minimises the disruption to Infrabuild’s current workflow since cobots can operate safely alongside human workers without the need for extensive guarding and offers the flexibility and the option to revert to manual operation if needed.

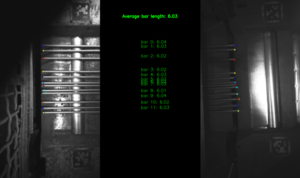

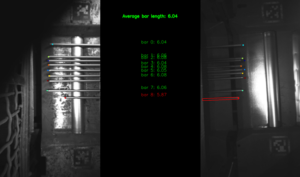

A major milestone was achieved during the demonstration, successfully showcasing the “shorts” detection and cobot bar tracking system functioning in a live factory environment. During the demonstration, the AI-based “shorts” detection system successfully detected short bars in real time. This information was communicated through a graphical user interface, displaying live video streams from two cameras mounted on InfraBuild’s conveyor line. The interface also featured coloured indicators: dots marking the detected start and end of a bar, its corresponding length displayed in the centre, and the average length per run. If a short bar was detected, a red bounding box highlighted it, and its corresponding length measurement changed from green to red, providing a clear visual cue for operators. The additional information provided from each production run, offers valuable insights for InfraBuild’s quality assurance processes. Additionally, InfraBuild noted that the vision system alone was a valuable addition, as it would enable operators on the factory floor to more quickly identify and remove defective bars when necessary.

By leveraging real-time detections from the vision system, the cobot dynamically adjusted its actions, indicating the bars identified as “shorts” by pointing at them. A laser mounted on the cobot’s end-effector highlighted these bars, allowing staff from the ACC and InfraBuild to clearly see the identified short bar. This milestone demonstrated the adaptability of vision-guided cobots, which, unlike traditional automation systems requiring structured environments, can respond dynamically to changing conditions in manufacturing processes.

This trial serves as a proof of concept for integrating robotic vision systems into InfraBuild’s broader production lines and offers valuable insights for other SME manufacturing companies looking to implement similar cobot-enabled automation solutions. By demonstrating the potential of vision-guided cobots, this initiative represents a step toward smarter, safer, and more flexible manufacturing systems. Showcasing a live cobot system in a factory was a first and major milestone for the ACC, proving that it is possible to address challenging problems found in industry. This achievement provides insight on the commercial viability of such technologies, marking a step for InfraBuild as they move toward the next phase of development.

Graphical user interface of the AI-based ’shorts’ detection system. The top image displays a run with no short bars detected. In the bottom image, a short bar is identified, highlighted by a red bounding box, and its length measurement in the centre of the interface changes from green to red, providing a clear visual indicator.